Equipping Culinary Excellence:

Your Strategic Guide to Commercial Kitchen Success

Unlock efficiency, safety, and profitability by mastering commercial kitchen equipment selection for your restaurant, café, or hotel.

- Step 1: Defining Your Culinary Core and Operational Needs

- Step 2: Optimizing Kitchen Space and Layout

- Step 3: Prioritizing Quality, Durability, and Compliance

- Step 4: Essential Equipment Categories and Their Roles

- Step 5: Budgeting and Financial Considerations

- Step 6: Researching Brands, Suppliers, and Support

- Step 7: Ongoing Maintenance and Scalability Planning

- Featured Video: Essential Insights for Commercial Kitchen Design

- Comparative Overview of Commercial Kitchen Equipment Categories

- FAQ: Your Commercial Kitchen Equipment Questions Answered

- Conclusion

- Recommended Further Exploration

- Tailor to Your Vision: Equipment choice is fundamentally driven by your specific menu, cooking style, and operational volume, ensuring every piece serves a clear purpose.

- Smart Space Utilization: A well-planned kitchen layout maximizes workflow efficiency, minimizes bottlenecks, and enhances staff safety and comfort.

- Invest in Longevity & Performance: Prioritize durable, energy-efficient equipment from reputable brands, balancing upfront costs with long-term savings and reliability.

Establishing or upgrading a commercial kitchen for a restaurant, café, or hotel involves critical decisions, none more impactful than selecting the right equipment. This process is far more than just purchasing appliances; it’s about crafting an environment that fosters efficiency, ensures food safety, and supports the culinary vision of your establishment. A strategic approach considers everything from menu demands and spatial constraints to budget limitations and regulatory compliance. By following a structured methodology, you can make informed choices that contribute significantly to your business’s long-term success and profitability.

Step 1: Defining Your Culinary Core and Operational Needs

Aligning Equipment with Your Menu and Service Model

The first and most crucial step in selecting commercial kitchen equipment is to intimately understand your establishment’s core identity. Your menu, cooking style, and service model are the primary determinants of your equipment needs. A café focusing on specialty coffees and pastries will have vastly different requirements than a fine dining restaurant specializing in complex, multi-course meals, or a hotel catering to diverse banqueting and room service demands.

Analyzing Your Menu and Cooking Techniques

Begin by meticulously analyzing your menu items. What preparation methods are involved? Do you require specialized equipment for baking, grilling, frying, or sous-vide cooking?Consider the specific processes your dishes undergo from raw ingredients to finished plates. For instance, a high-volume bakery will need industrial-grade ovens and mixers, whereas a salad bar will prioritize efficient choppers and refrigeration units. Mapping out these culinary processes ensures that every piece of equipment serves a direct, functional purpose.

A modern commercial kitchen layout, exemplifying efficient use of space and appropriate equipment for diverse culinary operations.

Assessing Capacity and Volume Requirements

Beyond the type of cuisine, consider your projected daily volume and peak service hours. An accurate estimation of customer traffic and food production helps determine the necessary capacity of your equipment. For example, a restaurant with high dinner service demand might need multiple fryers or a larger range, while a hotel serving breakfast buffets will require extensive holding equipment and high-capacity beverage dispensers. Over- or under- sizing equipment can lead to inefficiencies, increased operating costs, or customer dissatisfaction due to slow service. Factor in staff size and capabilities, as equipment should also complement their workflow and ease of use.

Step 2: Optimizing Kitchen Space and Layout

Designing for Efficiency and Ergonomics

The physical layout of your kitchen profoundly impacts operational efficiency, staff productivity, and safety. Before purchasing any equipment, it’s essential to meticulously plan your kitchen’s design, considering the available space and the logical flow of operations.

Strategic Zoning and Workflow

Divide your kitchen into distinct zones: receiving, storage, food preparation, cooking, plating, and dishwashing. Each zone should be equipped with the necessary tools and appliances, arranged to facilitate a seamless flow of food from delivery to service. For example, prep stations should be conveniently located near storage and cooking areas, while the pass-through should connect cooking to the dining area. This strategic zoning minimizes unnecessary movement, reduces bottlenecks, and improves overall speed of service.

An organized commercial kitchen demonstrating a clear separation of cooking stations and effective ventilation systems.

Measuring and Ergonomics

Accurately measure your kitchen dimensions and consider ergonomic principles. Equipment should fit comfortably without obstructing movement or creating cramped workspaces.

Aisles need to be wide enough (typically 36-48 inches) to allow staff to move freely and safely, even when carrying items. Consider the height and accessibility of controls, and ensure that frequently used items are within easy reach. A well-designed layout not only boosts efficiency but also enhances staff comfort and reduces the risk of workplace injuries.

Step 3: Prioritizing Quality, Durability, and Compliance

Investing in Long-Term Value and Safety

Commercial kitchens are demanding environments, requiring equipment that can withstand heavy use and adhere to stringent health and safety standards. Opting for quality and durability is an investment that pays off through extended lifespan, reduced maintenance, and consistent performance.

Material and Certification Standards

Prioritize equipment made from robust, easy-to-clean materials like stainless steel, which is highly durable and hygienic. Look for certifications such as NSF International, which ensures equipment meets public health and safety standards. These certifications are not merely labels; they indicate that the equipment has undergone rigorous testing for sanitation, materials, design, and performance, critical for maintaining food safety and complying with regulations.

Reliable Brands and Energy Efficiency

Research reputable brands known for their reliability, performance, and after-sales support. Brands like Vulcan, Hobart, and True Manufacturing are often cited for their quality and durability. While high-quality equipment may have a higher upfront cost, it typically offers better long-term value due to fewer breakdowns, lower repair costs, and extended operational life. Furthermore, consider energy-efficient models, often indicated by an ENERGY STAR rating. These appliances consume less power, significantly reducing utility bills and contributing to environmental sustainability.

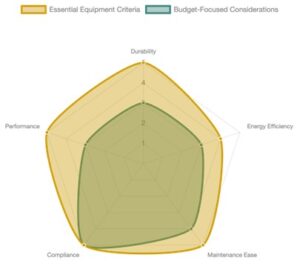

This radar chart illustrates the importance of various factors when selecting commercial kitchen equipment. “Essential Equipment Criteria” highlights high expectations across all key areas, while “Budget-Focused Considerations” shows a potential trade-off in durability and performance when prioritizing lower costs, though compliance remains non-negotiable

Step 4: Essential Equipment Categories and Their Roles

The Pillars of a Functional Commercial Kitchen

A well-equipped commercial kitchen balances a range of specialized tools across several core categories. Understanding these categories helps in creating a comprehensive list of necessities.

Cooking and Heating Equipment

This category forms the heart of any kitchen. It includes ranges, ovens (convection, combi, pizza), griddles, fryers, charbroilers, and specialized units like salamanders or tilting skillets. The choice here is directly tied to your menu and cooking volume. Combi ovens, for example, offer versatility for steaming, roasting, and baking, making them an excellent investment for diverse menus.

Refrigeration and Storage Solutions

Maintaining food freshness and safety is paramount. This includes walk-in coolers and freezers for bulk storage, reach-in refrigerators and freezers for easy access during service, and specialized units like prep-top refrigerators for ingredients at workstations. Adequate and appropriate storage prevents spoilage, reduces waste, and supports inventory management.

Food Preparation Equipment

Efficiency in prep work is crucial for smooth operations. Mixers, food processors, slicers, vegetable choppers, and robust prep tables are indispensable. Investing in high-quality prep tools not only speeds up processes but also ensures consistency and reduces manual labor.

Cleaning and Sanitation Systems

Hygiene is non-negotiable. Commercial dishwashers (rack, conveyer, or undercounter), multi-compartment sinks, powerful ventilation hoods, and grease traps are essential for maintaining a clean and safe environment. Proper ventilation is particularly critical for removing smoke, heat, and odors, ensuring air quality and code compliance.

Smallwares and Utensils

While often overlooked, high-quality smallwares, including knives, cutting boards, pots, pans, and serving utensils, significantly impact daily operations. Durable, well-maintained smallwares contribute to efficiency, food quality, and staff satisfaction.

Step 5: Budgeting and Financial Considerations

Balancing Cost with Value and Long-Term Savings

Establishing a realistic budget is fundamental. Commercial kitchen equipment represents a significant capital investment, and a strategic financial plan is essential for making sound purchasing decisions.

Prioritizing Investments

Allocate your budget wisely, prioritizing essential, high-use items that directly impact your core operations. For instance, quality refrigeration and primary cooking equipment should often take precedence. Consider a phased approach to purchasing, acquiring critical items first and then adding specialized equipment as your business grows and cash flow permits. Leasing options can also be explored to manage upfront costs for expensive items, freeing up capital for other operational needs.

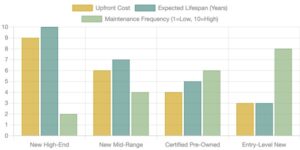

This bar chart compares different equipment purchasing strategies based on upfront cost, expected lifespan, and maintenance frequency. It illustrates that while new high-end equipment has a higher initial cost, it offers the longest lifespan and lowest maintenance.

Conversely, entry-level new equipment has the lowest upfront cost but typically requires more frequent maintenance and has a shorter lifespan. Certified pre-owned options offer a balanced approach.

Long-Term Operating Costs

Beyond the purchase price, consider installation costs, ongoing maintenance, and energy consumption. Energy-efficient models, while potentially more expensive initially, can lead to significant savings on utility bills over their lifespan. Factor in warranties and the availability of local service and parts to minimize downtime and unexpected repair expenses. Reading reviews and consulting with other professionals can provide valuable insights into the true cost of ownership for various equipment types.

Step 6: Researching Brands, Suppliers, and Support

Building Partnerships for Success

The relationship with your equipment suppliers is as important as the equipment itself. Choosing reliable brands and supportive partners ensures smooth operations and peace of mind.

Identifying Reputable Manufacturers

Look for manufacturers with a strong reputation for quality, innovation, and customer service. Brands like Vulcan, Hobart, and True Refrigeration are recognized industry leaders. Investigate their track record for durability, performance, and the availability of parts and service. Online reviews and industry publications can be valuable resources for this research.

Selecting Trustworthy Suppliers

Partner with suppliers who offer comprehensive support, including installation assistance, warranty fulfillment, and responsive maintenance services. A good supplier acts as a reliable partner, helping you troubleshoot issues and ensuring your equipment operates optimally.

Compare quotes from multiple suppliers, but don’t base your decision solely on price; evaluate the total value package, including service agreements and reputation.

This mindmap illustrates the interconnected steps and considerations involved in selecting commercial kitchen equipment. It highlights the iterative nature of the decision-making process, emphasizing how each factor influences the others, from initial needs assessment to long-term maintenance planning.

Step 7: Ongoing Maintenance and Scalability Planning

Ensuring Longevity and Adaptability

The journey doesn’t end once equipment is purchased and installed. Proper maintenance and a view towards future growth are crucial for maximizing your investment.

Implementing a Maintenance Schedule

Establish a rigorous preventive maintenance schedule for all equipment. Regular cleaning, inspections, and servicing by qualified technicians can significantly extend the lifespan of your appliances, prevent costly breakdowns, and ensure consistent performance. Train your staff on proper daily cleaning routines and basic troubleshooting for each piece of equipment.

Planning for Scalability and Future Needs

Consider the future growth of your business. Can your chosen equipment handle increased volume if your establishment expands? Opt for modular designs where possible, allowing for easier upgrades or additions without a complete overhaul of your kitchen. Thinking about scalability upfront ensures that your initial investment continues to serve your needs as your business evolves.

Featured Video: Essential Insights for Commercial Kitchen Design

Understanding the intricacies of commercial kitchen design is paramount to selecting the right equipment. This video provides a comprehensive overview of how thoughtful design influences efficiency and equipment choices.

The video “How to Design a Commercial Kitchen | A Comprehensive Guide” offers valuable perspectives on optimizing kitchen layouts, which directly impacts the types and sizes of equipment that can be effectively integrated. It emphasizes the importance of a holistic approach to kitchen planning.

Comparative Overview of Commercial Kitchen Equipment Categories

To further illustrate the diverse range of equipment and their typical applications, here’s a table summarizing key categories and their relevance:

|

Equipment Category |

Primary Function | Key Considerations for Selection |

Impact on Operations |

| Cooking Ranges & Ovens | Heating, baking, roasting, frying | Fuel type (gas/electric), capacity, footprint, ventilation requirements, versatility (e.g., combi ovens) | Core food preparation, throughput, menu flexibility |

| Refrigeration Units | Cold storage for raw ingredients and prepared foods | Size (reach-in, walk-in), temperature control, energy efficiency, accessibility, type (fridge, freezer, prep-top) | Food safety, waste reduction, ingredient freshness |

| Food Prep Equipment | Chopping, mixing, slicing, blending ingredients | Motor power, blade quality, ease of cleaning, safety features, capacity (e.g., mixers, food processors) | Preparation speed, consistency, labor efficiency |

| Dishwashing & Sanitation | Cleaning and sanitizing dishes, utensils, and equipment | Wash cycle speed, water usage, chemical compatibility, heat requirements, space (e.g., commercial dishwashers) | Hygiene, compliance, turnaround time for tableware |

| Ventilation Systems | Removing smoke, grease, heat, and odors | Capture efficiency, noise level, exhaust power, filter type, compliance with fire codes (hoods, exhaust fans) | Air quality, staff comfort, safety, regulatory compliance |

FAQ: Your Commercial Kitchen Equipment Questions Answered

What is the most important factor when choosing commercial kitchen equipment?

The most important factor is aligning the equipment with your specific menu and operational needs. Your menu dictates the types of cooking processes required, while your anticipated volume determines the capacity. Without this foundational understanding, even high-quality equipment can be mismatched and inefficient.

How can I balance budget constraints with quality requirements?

Balance budget with quality by prioritizing essential equipment for your core operations. Invest in new, high-quality items for critical, high-use appliances like ranges and refrigeration, which offer better long-term value. For less critical items, consider certified pre-owned equipment or explore leasing options to manage upfront costs and preserve capital. Always factor in long-term operating costs like energy efficiency and maintenance.

Why is kitchen layout so important for equipment selection?

Kitchen layout is crucial because it directly impacts workflow efficiency, staff safety, and overall productivity. A well-planned layout ensures that equipment is placed logically, minimizing movement and preventing bottlenecks. Equipment must fit comfortably within the designated space while allowing for safe and ergonomic operation. Poor layout can lead to inefficiencies, increased labor costs, and higher risk of accidents.

What certifications should I look for in commercial kitchen equipment?

Always look for NSF International certification, which ensures equipment meets stringent public health and safety standards for materials, design, and sanitation. For energy efficiency, look for the ENERGY STAR rating. These certifications are vital for regulatory compliance and ensuring that your equipment is safe, hygienic, and cost-effective to operate.

Conclusion

Choosing the right commercial kitchen equipment is a multifaceted strategic decision that profoundly impacts the success and longevity of your restaurant, café, or hotel. By systematically assessing your culinary needs, optimizing your kitchen layout, prioritizing quality and compliance, and meticulously managing your budget, you lay a robust foundation for operational excellence. Investing in durable, energy-efficient equipment from reputable brands, supported by reliable suppliers, ensures not only immediate efficiency but also long- term profitability and adaptability. Remember, a well-equipped kitchen is the heart of a thriving culinary business, driving satisfaction for both staff and customers.

Recommended Further Exploration

Advanced commercial kitchen layout design principles for optimal flow

Maximizing energy efficiency in commercial kitchen equipment to reduce operating costs

Strategies for financing and leasing commercial kitchen equipment

Understanding the impact of food safety certifications on equipment selection